top of page

Project

Earthseed Frequencies: Interactive Plush Mound with Vibration

Rooted in Octavia E. Butler’s Parable series, this vibrating mound offers a tactile, sensory experience where vibration becomes a language of change. Inspired by Lauren Olamina’s belief system, it invites visitors to sit with the Earth, tune in, and feel transformation from the ground up.

Project Overview

Installation

Wired for Wonder, a Getty-sponsored exhibit at the Kidspace Museum of Pasadena

Team

Kia McCormick

Brett Bognar

Zander Tate

Industrial Design, Project Management, Fabrication

Fabrication

Fabrication

Client

Sabela Grimes, Creative Director of Earthseed Frequencies for Wired for Wonder

Key Skills

Rhino + Grasshopper, CNC CAM & cutting, woodworking, upholstery, sewing, project management

Context

Sabela Grimes invited me to create an installation as part of his exhibit for the Kidspace Childrens Museum of Pasadena— he was looking to create a space where children could observe, listen, and reflect on projected audio-visual content. Inspired by Octavia E. Butler’s Parable of the Sower and Lauren Olamina’s Earthseed philosophy, the piece was designed to embody the belief that “God is Change.”

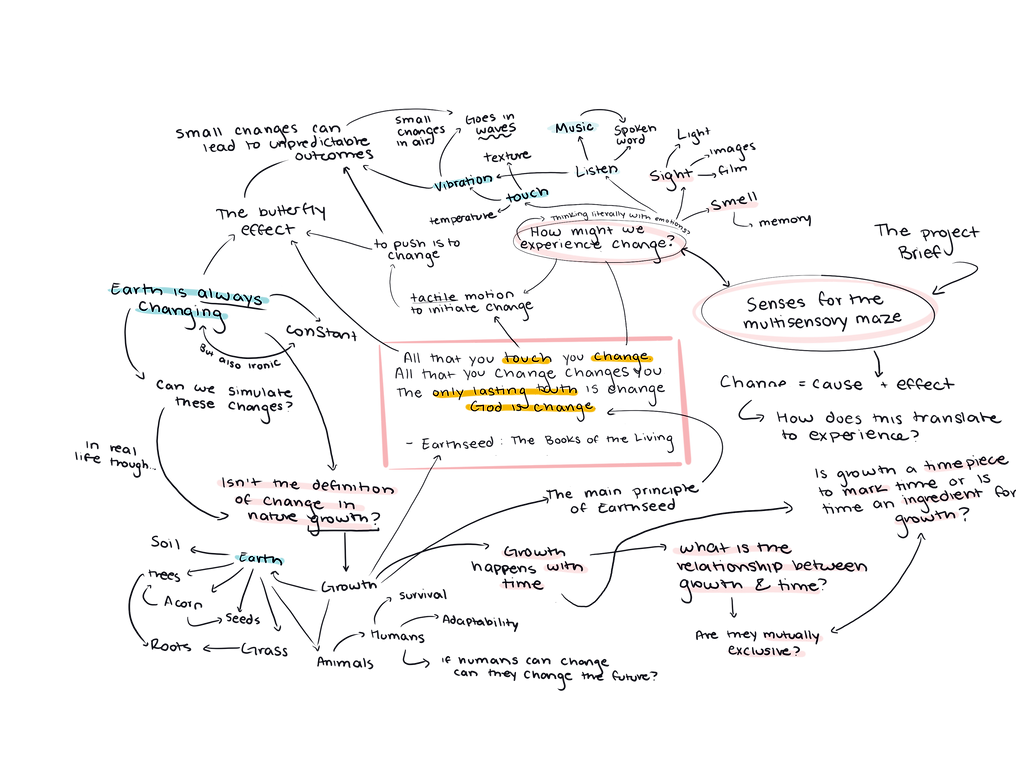

With that we began the creation process by sitting down and creating a mindmap

Mindmap Takeaways

Initial Concepts

Projection Mapping

Moodboard

Initial Sketches

Initial Renders

.png)

Concept: Vibration Mound with Beanbag

Final Sketch

Vibration Mound with Beanbag

Final Render

Bass shakers create a haptic experience that synchronizes with the audio and visual projections on the wall.

Building/Fabrication

1. 3D Modeling the structure on Rhino

During the construction process I had to keep in mind that the structure had to be strong and secure but could also be taken apart and rebuilt for easy transport and removal at the end of the exhibit

Dimensions in space

Bass shaker placement concepts

2ft by 4ft sections in the internal structure

Waffle structure created with grasshopper

Waffle is broken down into 15 different sections for easy construction

Registration holes to align the top mound

Bass shakers to be installed under top plate

2. CNC Machining the internal structure of the mounds

3D modeled 4 by 8ft sheets of 3/4in plywood for CNC

4 by 8 CNC router

Routed off tabs post CNC job completed

3. Assembling the internal structure of the mounds

3D Model

labeling system to allow for ease of assembly later

Physical Model

Tolerances fit! Assembled with wood glue and screws

Each of the 15 sections coming together to form the structure

Posts added for stability and to add height to the internal structure also to accommodate foam thickness

Top mound construction

4. Applying the chicken wire to create an organic form

Affordable and efficient way to generate a preliminary surface for the foam to adhere to later

Chicken wire application with staple gun

5. Using paper mache to create a surface for the foam to adhere to

paper mache with recycled bedsheets to form a more coherent surface for the foam to adhere to

6. Adhering the foam

Placing the foam order

Organized foam with labeling system

Foam delivered!

Adhering foam to structure by section to allow for the structure to still be taken apart

7. Designed patterns, cut, and sewed faux fur to custom-fit the mounds

Used Rhino to develop a sewing pattern

Sewing top and bottom mound faux fur coverings

Created a preliminary pattern to protect the foam and make sure the pattern fit

Onsite Installation

1. Moving the mounds to the exhibit site

Packed up mound structures in a 10ft uhaul

Drove Uhaul to Kidspace children’s museum

2. Assembling the internal structure

Assembled the structure together with screws

Installed Bass shakers underneath top plate

3. Final upholstery and, assembly of the two mounds

Added a final layer of batting

Pulled faux fur covering over and secured it underneath the structure

Final Vaccum

Testing the structure onsite

Final Exhibition

Projection mapping

Opening Day

bottom of page